Round tubing 14.

Bending 11 gauge aluminum.

Formulas and data.

304 stainless steel 18 gauge.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

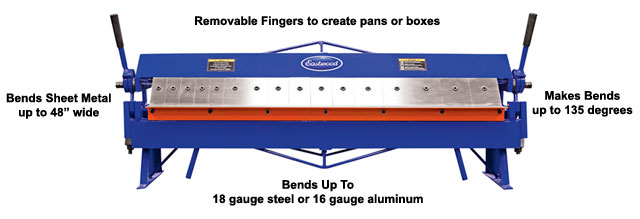

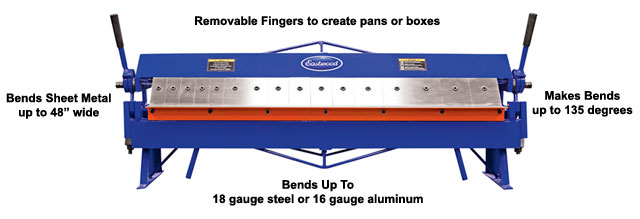

I think a small press brake will do what you want it depends on the width of the aluminum.

Use the chart below to convert standard gauge numbers in decimals of an inch for sheet steel aluminum and stainless steel.

0 017453 x 90 x 0 020 0 33 x 0 024 0 0438558984 inch bend allowance.

It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

You will use the protractor to gauge the brake as you bend the metal little by little.

Bending a brittle metal beyond its limits could cause the metal to snap and break.

We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts.

Each aspect of sheet metal bending is important to consider when determining the proper tonnage for the desired bend.

Use at your own risk.

Aluminized steel 14 gauge.

Because of the varying thicknesses a gauge chart should be used to ensure the metal meets the required dimensions.

The steel weights are tweaked for mechanical tubing and will be less accurate for structural tubing.

The gauge system has long history in metal fabrication.

I fabricated a small bending brake using plans from the miller welding web site and it will bend 1 5 wide 125 thick steel.

Step 2 slide the angle iron into the jaws of the vise so that it lays flat the length of the piece of metal you are going to bend.

Metal gauges below you ll find the info you need with our sheet steel stainless steel and aluminum sheet metal charts.

Typically i bend 12 15 widths of 18 gauge steel.

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase.

Mild steel 10 11 gauge.

Round tubing 16 gauge.

Cut the section of metal out or otherwise prepare the metal to be bent by removing any burrs or sharp edges.

Keep in mind that some metals are more brittle than others.

The moduli of elasticity used are 29 700 000 psi for steel and 10 000 000 psi for aluminum.

Or you ll be sorry.

Bend radii minimum bend sizes.

For example in one gauge system 18 gauge steel measures 0 0478 inches thick but 18 gauge aluminum is 0 0403 inches thick.

As an example if you want to bend 24 gauge sheet metal at a 90 angle the calculation would be.

History of the gauge system.

If the deflection is large enough to permanently bend the tube then all bets are off.

Round tubing 18 gauge.